BMW showcases Light Weight Construction Parts

This week, BMW is hosting their annual Innovation Days event. Every year, the Munich-based automaker showcases some of their hereafter technologies, and the primary theme this year is EfficientDynamics.

In the press release issued today, an entire section is focused on Light Weight Construction parts and BMW's advocacy in this area. From CFRP and aluminum bonnets, to carbon fiber seats, BMW's focuse for the futurity is on weight reduction. Hither is the section from the lengthy press release:

Intelligent lightweight construction as a evolution principle for Efficient Dynamics: New perspectives on weight improvement.

Thanks to Efficient Dynamics the BMW Group is succeeding in continuously reducing the consumption and emission values of electric current and futurity models and simultaneously increasing the pleasance of driving characterised by dynamics and agility. Furthermore, additional requirements, such equally active and passive safety and driving comfort, are taken into business relationship. For the solution of the conflict of interests between the many demands made on premium segment vehicles and the pursuit of maximum efficiency non only efficiency optimisation of the drive system, but above all weight optimisation plays a vital part. The concept of intelligent lightweight construction creates ideal conditions for the realisation of the unmistakable character of a BMW or a MINI model at equally low a vehicle weight as possible.

Thanks to Efficient Dynamics the BMW Group is succeeding in continuously reducing the consumption and emission values of electric current and futurity models and simultaneously increasing the pleasance of driving characterised by dynamics and agility. Furthermore, additional requirements, such equally active and passive safety and driving comfort, are taken into business relationship. For the solution of the conflict of interests between the many demands made on premium segment vehicles and the pursuit of maximum efficiency non only efficiency optimisation of the drive system, but above all weight optimisation plays a vital part. The concept of intelligent lightweight construction creates ideal conditions for the realisation of the unmistakable character of a BMW or a MINI model at equally low a vehicle weight as possible.

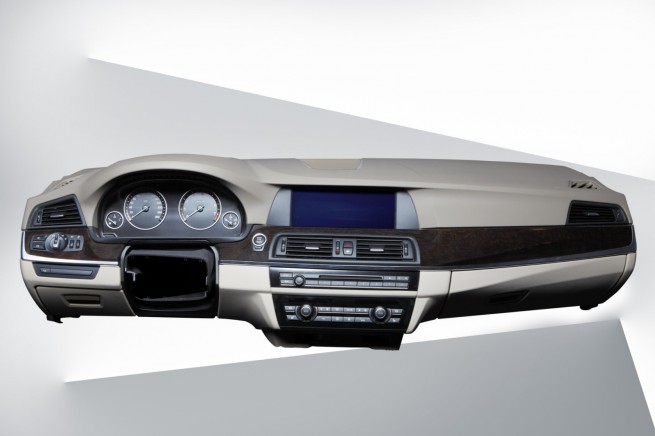

The principle of intelligent lightweight construction applies and is consistently pursued in all sectors of machine evolution – from trunk and engine construction to chassis applied science and interior blueprint. The BMW Group has established a process footstep, which during the predevelopment phase already generates ideas for alternative materials or constructional designs leading to an optimisation of vehicle weight. Innovative production processes expand the range of feasible solutions. Autonomously from alloys and plastics, renewable raw materials and foams, also increasing utilize of composites and hybrid materials is made.

The demands imposed on every lightweight construction solution are sophisticated. Each new material must at to the lowest degree equal the previously used cloth in functionality and reliability and at the same fourth dimension be significantly lighter. Furthermore, the production costs including energy and raw materials and their recyclability are taken into account in the total evaluation. Thus the utilisation of innovative composites became possible only afterward the development of modernistic recycling processes. These ensure that information technology is as well possible to completely recycle fabric combinations after their normal utilisation.

More prophylactic, unique agility, optimised weight: innovative textile mix in trunk structure.

The new BMW v Series is an impressive example for the progress achievable through intelligent lightweight construction in the optimisation of body weight. During the evolution of the saloon and touring models far stricter safety specifications had to exist met than had applied for the previous models. At the same time the agility and comfort characteristics typical for the BMW v Series were to exist developed further.

Compared to the previous model the average stability of the new 5 Series Saloon'southward torso structure has been increased by 55 percent. Furthermore, the new model shows the typical BMW weight distribution of practically 50:50 between front and rear axles. The high stability of the body and the wellbalanced axle load distribution are complemented by optimised total weight and thus farther better both efficiency and active treatment of the new BMW v Series.

The solution to the disharmonize of interests between crash safety and condolement on the one manus and weight optimisation, agility and efficiency on the other was achieved through a precisely defined material mix. The new BMW 5 Series has doors, forepart side walls and a bonnet made of aluminium. Solely through the utilise of aluminium doors a weight reduction per vehicle of 23 kilograms compared to a conventional steel construction was achieved. Furthermore, a far higher proportion of hot-formed steel grades compared to the previous model was used. These high-strength steel grades, which involve more elaborate processing, provide – at a lower weight – higher force and stability using less fabric. Progress in production engineering makes it possible to increase the proportion of high strength steel grades with each model generation. Thus the steadily increasing demands regarding crash safety tin can be met without an increment in weight.

Optimised material utilisation in the carbon production.

BMW already plays a leading role in the utilisation of carbon fibre reinforced plastic (CFRP) in the automotive industry, which volition exist considerably increased when series product of the BMW i3 and BMW i8 models appear for 2013 commences. Both models have a passenger cell produced from CFRP, which combines extreme stability with a far lower weight compared to steel, but also to aluminium. This represents the first introduction of this cloth, known upwardly till at present from Formula One racing and the aviation industry, to big-calibration serial production of cars.

In the medium and long term, non just the models produced under a subbrand of BMW volition profit from this innovative construction. During production development for the rider cells of the BMW i3 and BMW i8 models an innovative procedure for further processing of the cuttings from the carbon fibre mats and textiles was conceived. In future these can be used 100 percent for the production of trunk components. In this fashion it volition be possible to equip other models with extremely calorie-free and high-course carbon fibre components. Increasing the carbon fibre proportion throughout all segments will thus be possible at considerably lower costs than hitherto.

The cuttings are subjected to a newly developed process, during which the carbon fibre cuttings of varying length are woven into CFRP mats of the required size and then, in exactly the way as the original material, dipped in artificial resin and cured. The force of the material produced in this manner is several times college than that of carbon fibre reinforced plastic. It equals the strength of a conventional steel component – at a weight reduced to less than a quarter.

In the course of predevelopment utilisation of processed CFRP for example was tested in the prototype of a bonnet for a BMW M model. The lid consists of 2 carbon layers enclosing either a Nomex plastic or a recycled-paper honeycomb. Also the prototype of a seat shell was produced from the material created through the new engineering. The BMW M GmbH has already gathered extensive experience in the utilisation of CFRP in serial evolution. For example, the current BMW M3 Coupé has a carbon fibre roof.

Less weight, lower dissonance emissions: focus of innovation is on acoustic lightweight construction in the drive area.

With continuously increasing aluminium content and the use of even lighter magnesium for engine construction the BMW Group has significantly reduced the average weight of bulldoze units during contempo times. In addition to this, the engine evolution specialists are working on innovative components, by

means of which the noise emissions of petrol and diesel engines tin can exist further reduced. Ane instance here is the audio-visual encapsulation for the particulate filter of diesel fuel engines. This provides a clearly noticeable reduction in the dissonance levels both inside and exterior of the vehicle. Thanks to the efficient encapsulation of the particulate filter, part of the sound insulation of the underbody cowling, the bulkhead and the front end axle tin be dispensed with, so that the total vehicle weight is reduced. Furthermore, the new casing has non simply an acoustic, simply likewise a heat insulating function. After a cold showtime an encapsulated particulate filter reaches its optimal operating temperature faster. The new construction blueprint thus improves the durability of the frazzle gas handling system.

A farther acoustic lightweight construction measure is practical at the engine forepart. A sound insulating of the belt drive, the and so-chosen engine front bulkhead, absorbs the drive noises coming from the crankcase and the cylinder head, which are of high frequency and therefore unpleasant to the ear. The foam material used for the engine front end bulkhead has very depression weight just splendid audio absorbance backdrop.

The encapsulation of the oil sump provides audio insulation immediately at source. Oil sumps fabricated of metal bear witness to be particularly effective resonance bodies for the vibrations from the crankcase and crankshaft. This undesired effect is compensated for past insulation equanimous of fibre fabric combined with a layer of moulded foam. Due to the deliberately selected material combination the noise emissions occurring are not only attenuated just also absorbed.

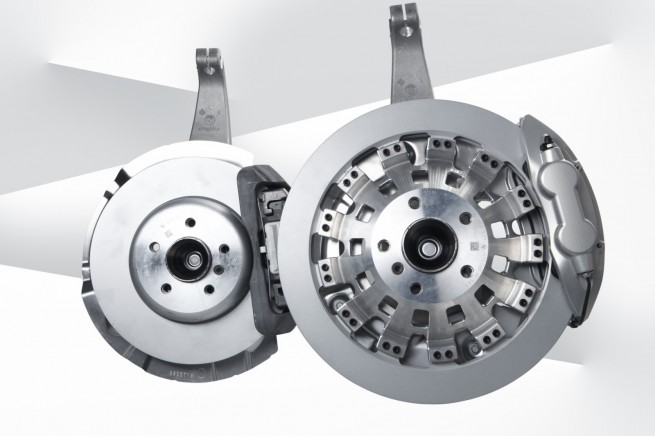

Chassis components: reduced weight, improved driving pleasure and efficiency.

The lightweight structure methods in the chassis sector are numerous and they have a direct positive influence on driving pleasure. Every reduction of unsprung, and in detail, of rotating masses has a direct effect on the agility of the vehicle. That is why the BMW Group places particular value in weight optimisation of the suspension and restriction systems. With the introduction of the chassis made well-nigh completely of aluminium in 1996, BMW ready standards for agility and driving pleasance in all segments. Furthermore, the weight optimisation of chassis engineering science provides ideal preconditions for greatly improved comfort, for shorter braking distances and for a reduced load acting on the vehicle trunk.

Among those lightweight construction measures performed on the electric current BMW series models are the weight-optimised drive shafts with spur gearing (weight reduction 0.viii kilograms per vehicle on models with BMW xDrive), a steering cavalcade instance fabricated of magnesium (up to 2.0 kilograms) as well as a human foot pedal mounting made of plastic and a plastic clutch pedal (upwards to 1.5 kilograms). With a stabiliser retaining bracket and an articulated column made from fibre reinforced plastic the vehicle weight in each case is reduced by 0.4 kilograms. A gearbox cross member made from fibre reinforced thermoplastic is i.0 kilograms lighter than the aluminium component previously used.

Every bit office of a predevelopment programme spanning all chassis variants the BMW Group development engineers are also working on weight-optimising innovations, through which a further reduction of mass to the extent of over 20 kilograms can be achieved. Thus for example suspension leap systems made from glass fibre reinforced plastic, which brand each vehicle up to vi kilograms lighter, every bit well equally extremely weight reduced high-performance braking units are in the predevelopment stage. The construction, consisting of an aluminium stock-still calliper and a lightweight brake disc, reduces the vehicle weight by virtually 8.0 kilograms compared to the restriction units already in employ in the series production vehicles, which are fitted with an aluminium chamber and an aluminium floating calliper.

[Source: BMW ]

Source: https://www.bmwblog.com/2011/04/04/bmw-showcases-light-weight-construction-parts/

0 Response to "BMW showcases Light Weight Construction Parts"

Post a Comment